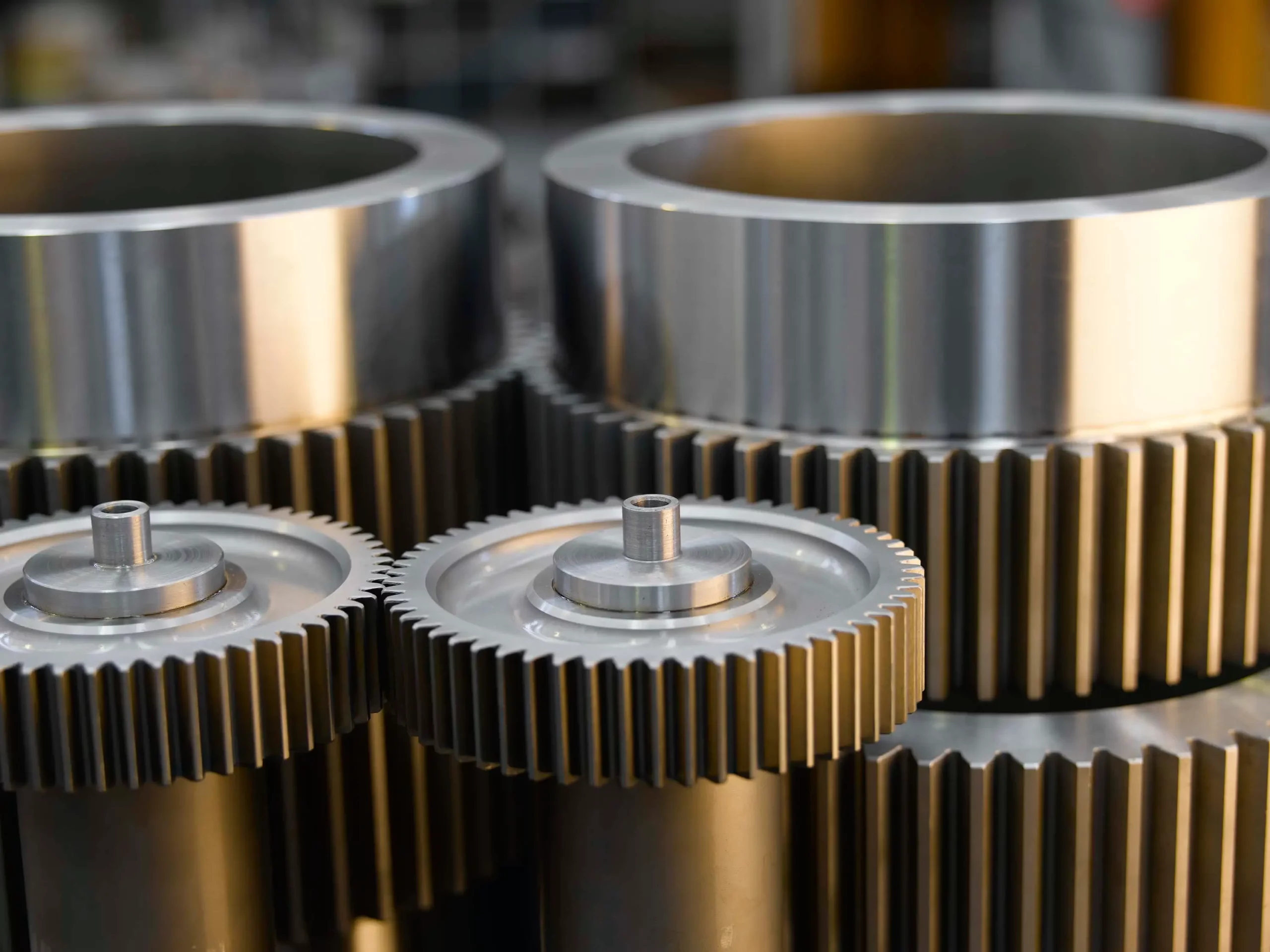

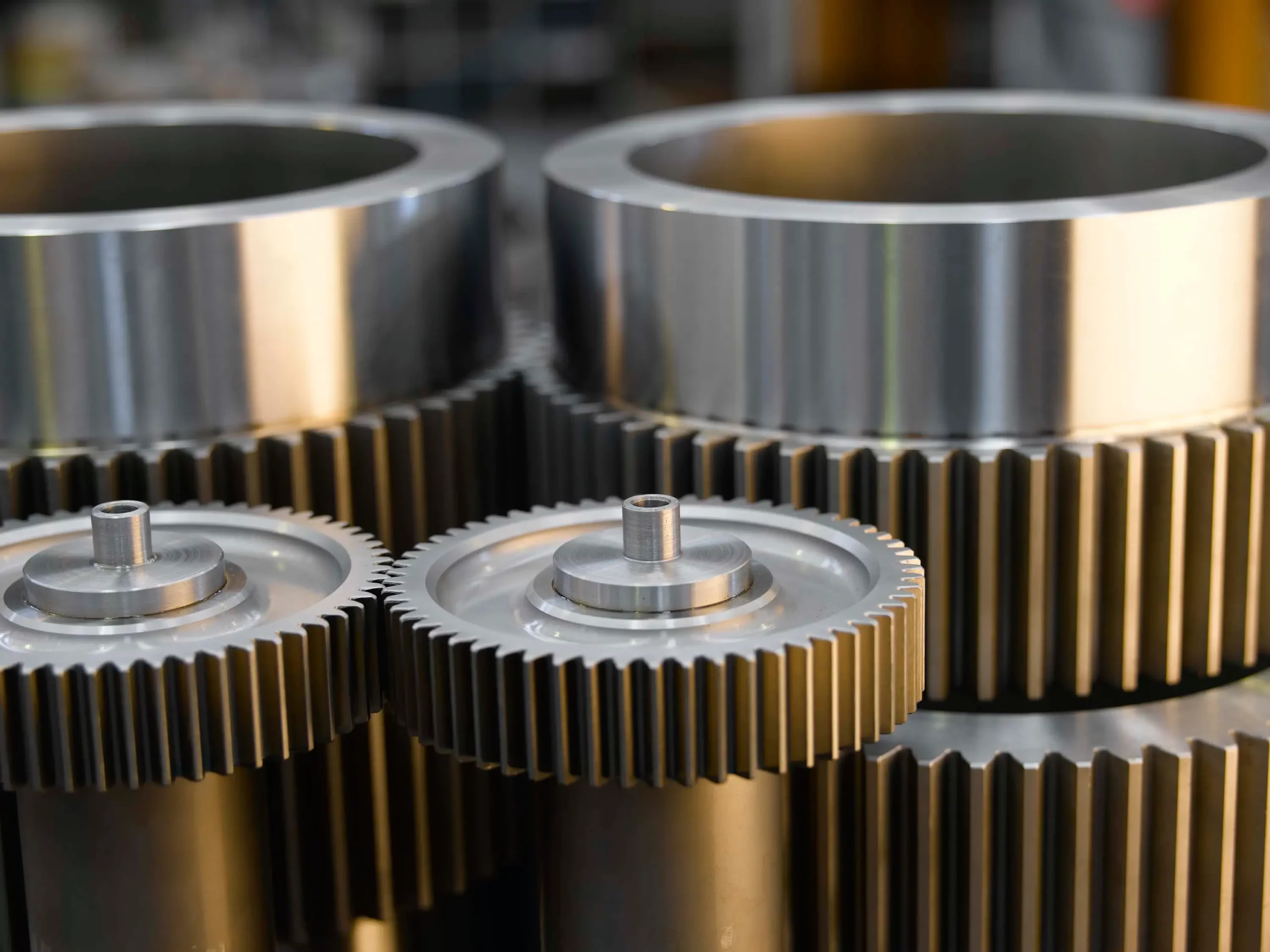

Our core business is manufacturing high quality gears and surfacing industrial gear boxes, large or small

Driving New Zealand’s Future in Gear Technology

We offer 40+ years’ experience with 30+ highly skilled personnel. AH Gears continually invests in the best equipment and tooling available. We employ staff who are experts in their field and who are committed to providing quality, cost effective gearboxes, that exceed customers’ expectations.

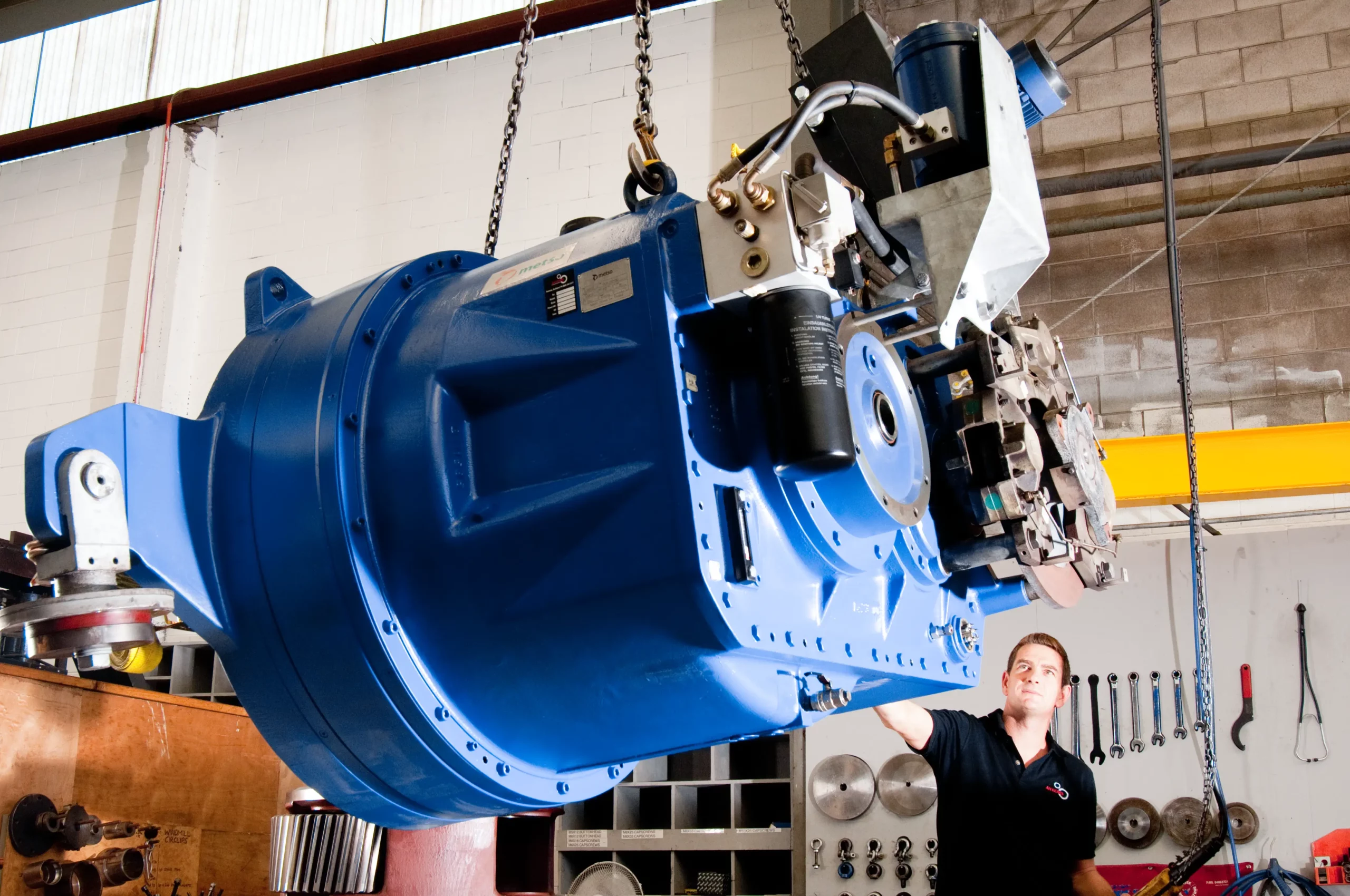

Gearbox Overhaul and Maintenance

We offer highly skilled fitters who overhaul gearboxes both on and off-site

AH Gears offer on and offsite solutions for monitoring gearboxes and equipment. These include vibration and temperature monitoring, oil sampling and gearbox servicing that can prevent expensive failures.

In the event of a failure, we offer highly trained engineers who can either dismantle on-site when possible or move from site to repair.

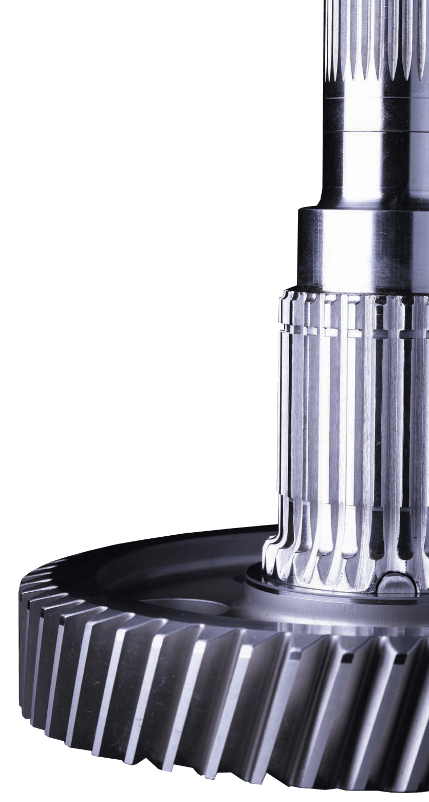

CNC Gear Cutting and Grinding

AH Gears are specialists in gear cutting and precision cnc gear grinding.

With our range of precision gear grinding machines we can produce very accurate ground gear profiles suitable for the most demanding engineering applications. Using our Hofler 800 CNC gear grinder we are able to reduce setup times while producing gears to the highest quality ensuring the long life of the gears.

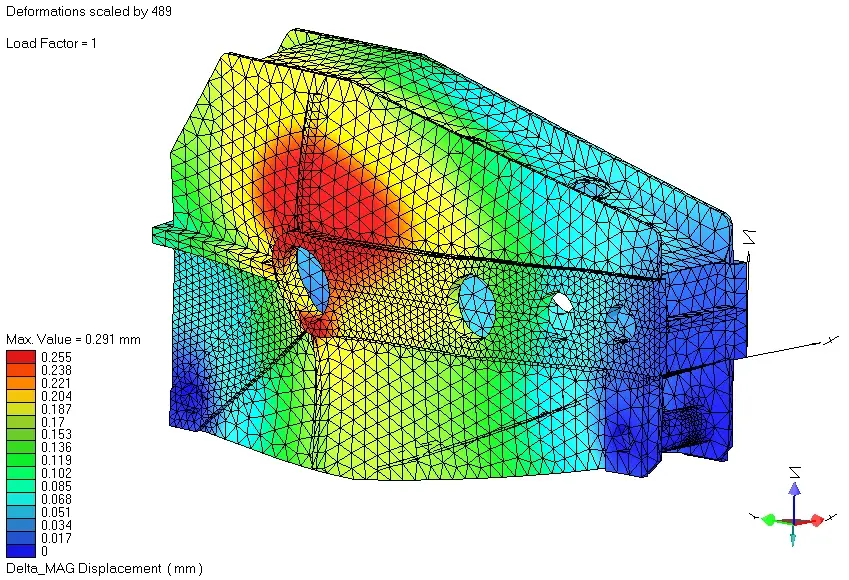

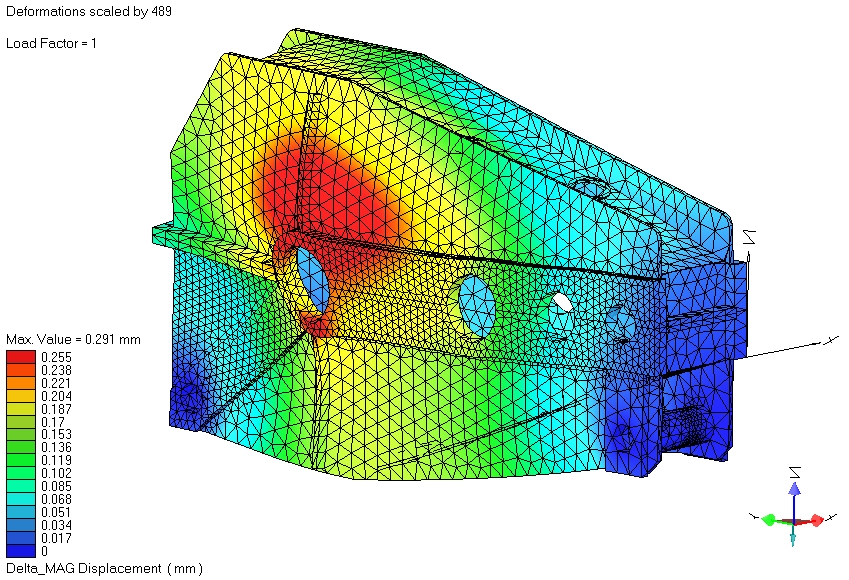

Design and Manufacture

Our highly experienced engineers utilise up to date design software that includes industry recognised gear calculation software and Solid Works computer aided design programme.

This combined with over 30 years design experience enables us to provide you with innovative and reliable gearbox solutions.

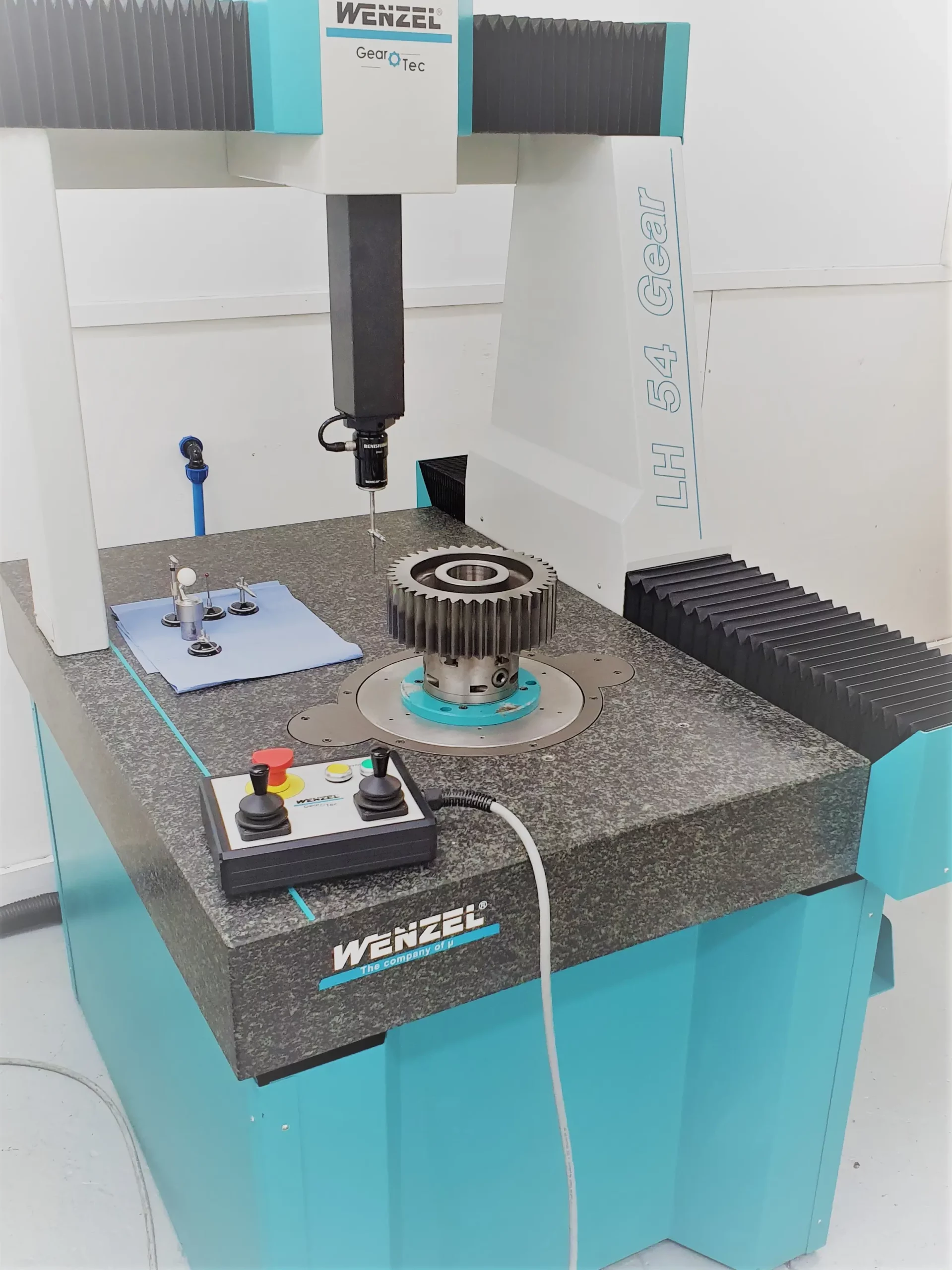

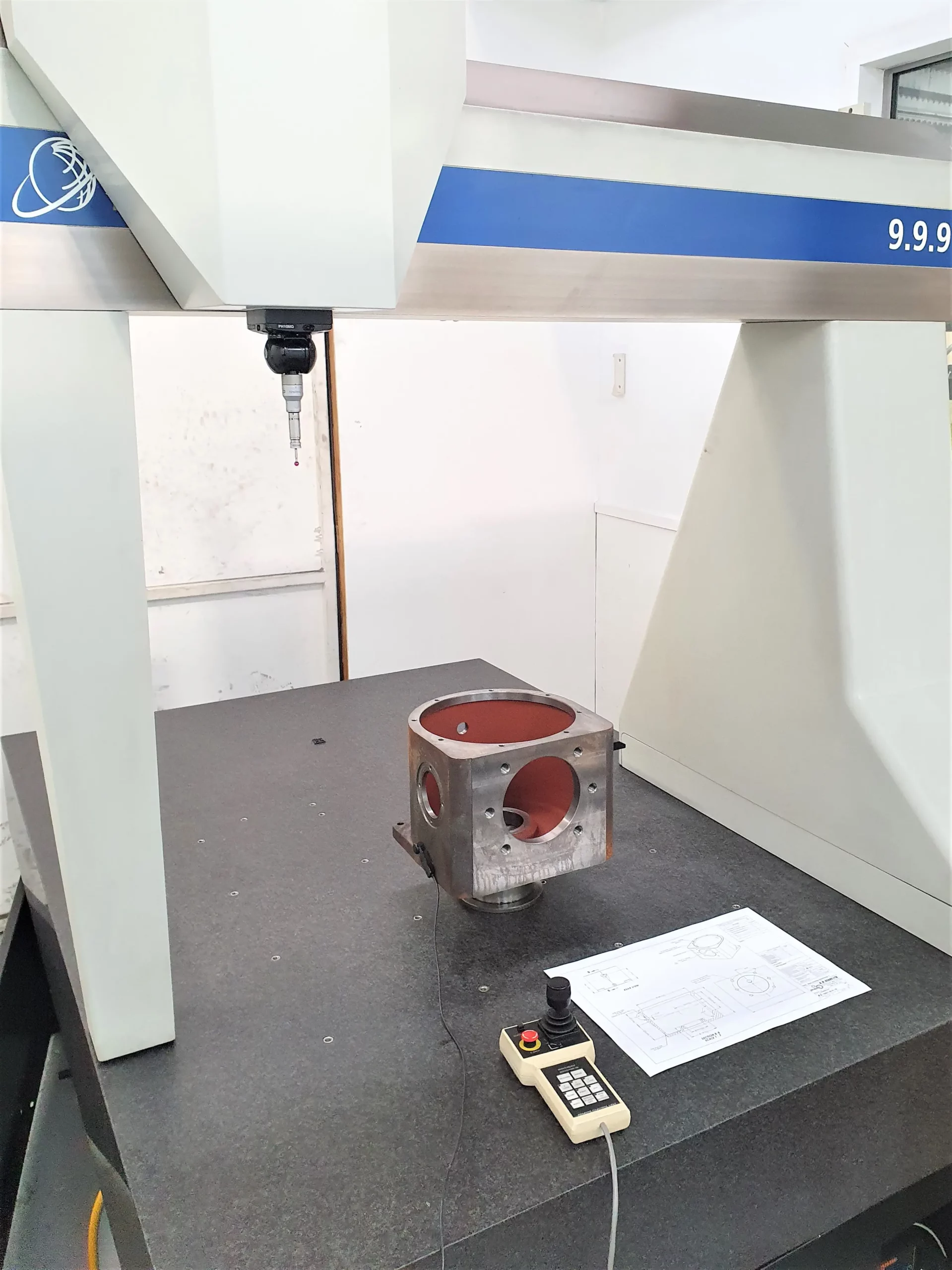

Quality and Inspection

Gears are inspected on our Swiss made Maag gear inspection machine that measures gear profiles, helix angles and tooth pitching. The gear inspection machine is regularly checked against calibrated masters to ensure accuracy and reliability to international standards.

Precision Machining

Our Capability includes:

- CNC Turning

- Milling – 4 and 5 axis

- Large horizontal boring

- Cylindrical grinding

- 20T Overhead lifting capacity

- Inspection equipment

Our Gallery

AH Gears have provided services to clients such as Windflow Technology, Trust Power, OJI, New Zealand Steel, Fisher & Paykel and many more.